Manufacturing

Ensuring that software works for your business

- Productivity Challenges

Struggling with Manufacturing Challenges?

Managing a seamless production process is crucial for manufacturers. Without a structured system, businesses face:

- Inefficient raw material planning based on production needs.

- Lack of end-to-end procurement control for quantity, quality, and cost.

- Difficulty in managing Make-to-Order & Make-to-Stock production.

- Complexities in material requirement planning for work orders.

- Challenges in multistage production processes and quality checks.

- Inaccurate production costing and variance analysis.

- Challenges Facing Manufacturers

Say Goodbye to the Challenges Holding You Back

Inventory Inaccuracy

Overstocking or stockouts disrupt production.

Industry Problems

43% of manufacturers struggle with inventory visibility. (Source: MESA Intl.)

How EPRNext Solves it

ERPNext provides real-time inventory tracking across multiple warehouses.

Production Delays

Poor scheduling leads to inefficiency.

Industry Problems

73% of manufacturers say unplanned downtime affects productivity. (Source: Deloitte)

How EPRNext Solves it

Automated production planning eliminates scheduling errors.

Disconnected Processes

Multiple departments operate in silos.

Industry Problems

67% of manufacturers use cc for operations. (Source: Industry Week)

How EPRNext Solves it

ERPNext integrates sales, procurement, and production into one connected platform.

Inconsistent Demand Forecasting

Leads to overproduction or shortages.

Industry Problems

61% of manufacturers say inaccurate forecasts increase waste and lower profits. (Source: PwC)

How EPRNext Solves it

ERPNext uses data-driven forecasting to improve accuracy.

Lack of Visibility into Operations

No real-time tracking.

Industry Problems

45% of businesses struggle to track work orders, resources, and WIP. (Source: McKinsey)

How EPRNext Solves it

ERPNext gives real-time dashboards & insights for better decision-making.

Compliance & Quality Challenges

Maintaining product quality and meeting regulatory standards.

Industry Problems

80% of manufacturers say compliance & quality directly impact costs. (Source: AMR Research)

How EPRNext Solves it

Built-in quality control & audit tracking ensures consistency.

- Manufacturing Solutions Features

Core Features of Our erpnext Manufacturing Module

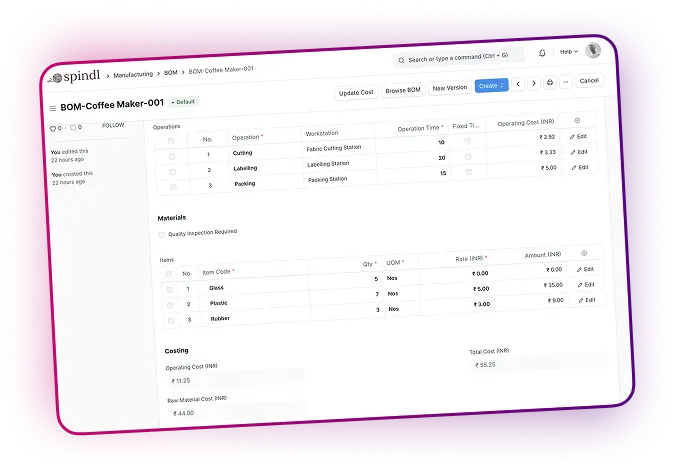

Bill Of Material (BOM)

A bill of material is at the heart of any cloud manufacturing software, and a well-defined BOM ensures robustness and accuracy. ERPNext’s BOM is hierarchical, with the finished product at the top. It also includes product codes, part descriptions, quantities, costs and additional specifications.

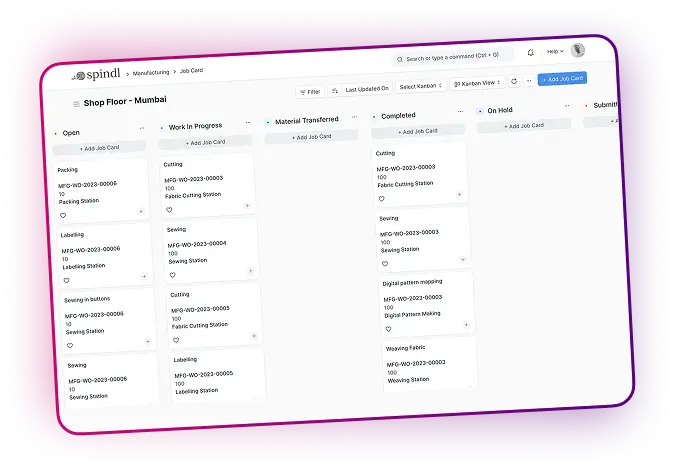

Real Time Operation Visibility

With ERPNext’s job cards, operations and workstations features, you can automatically capture daily activities on your shop floor. View real-time status of the job work being done to manufacture products, the location of every workstation, employee assignments, and each work order’s current status and pending steps — all in one screen.

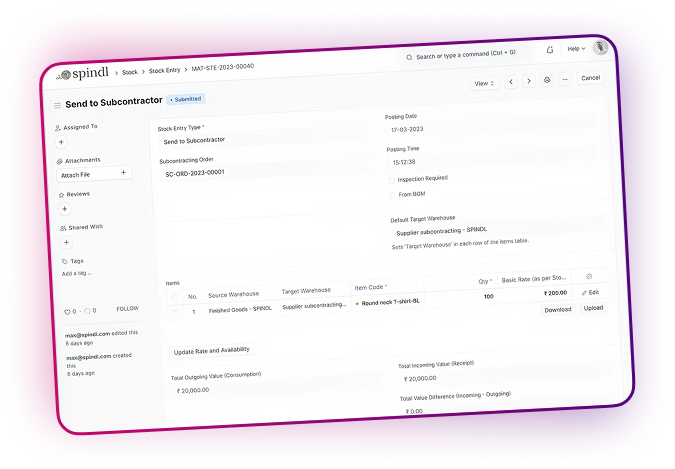

Subcontracting

Does your business involve outsourcing processes to a supplier? Check out the subcontracting feature in ERPNext. It makes it easy to supply raw materials and track suppliers’ labor and operations. Finished goods are valued based on the cost of raw materials and procured services.

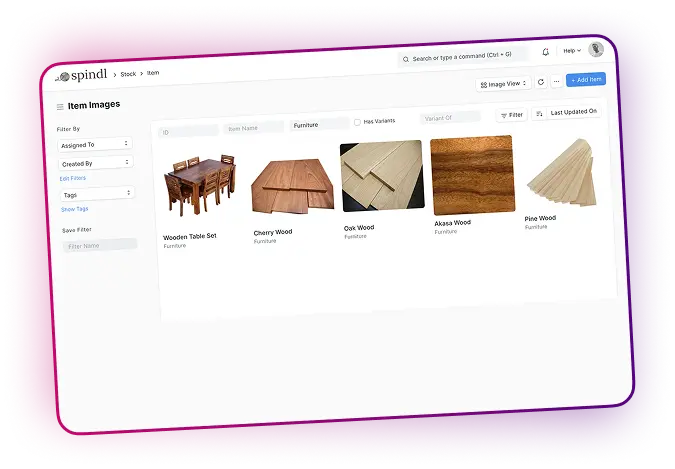

Item Variants

Suppose you produce t-shirts in different sizes and colors. You’ll need to track each type of t-shirt and its variants, known as item variants. In ERPNext, the primary item is stored as an item template, and each of the variations is stored as an item variant. You can store any attribute, such as color or shape, for each item variant.

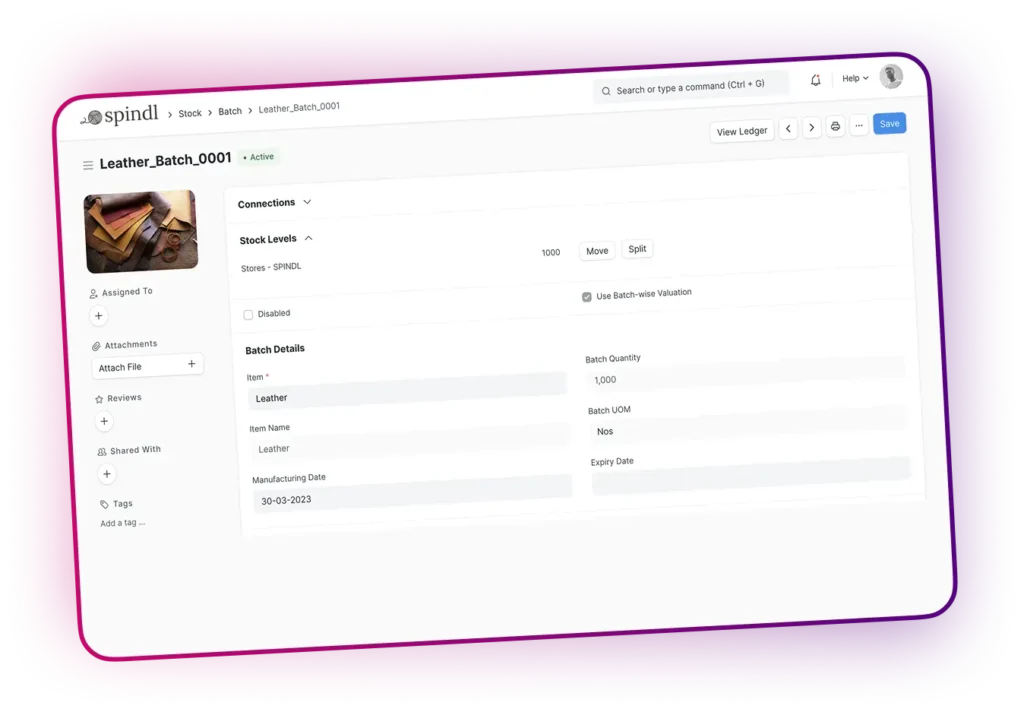

Batched Inventory

With ERPNext’s integrated inventory, managing batched items is simple. Its real-time view of product availability maintains each batch’s manufacturing dates, expiration dates, and other details. You can even scan item barcodes with your device camera to quickly search through your stock and make data-driven decisions.

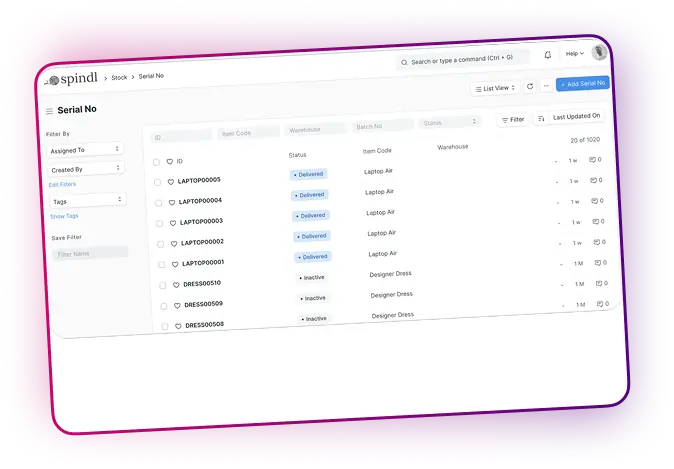

Serialized Inventory

Use serial numbers to uniquely identify units. Set up naming series, and ERPNext will automatically create serial numbers for new stock. You can even scan item barcodes via your device camera for easy search through all your stock.

- ERPNext workflows

basic workflows

-

Manufacturing Module

Manufacturing Module

-

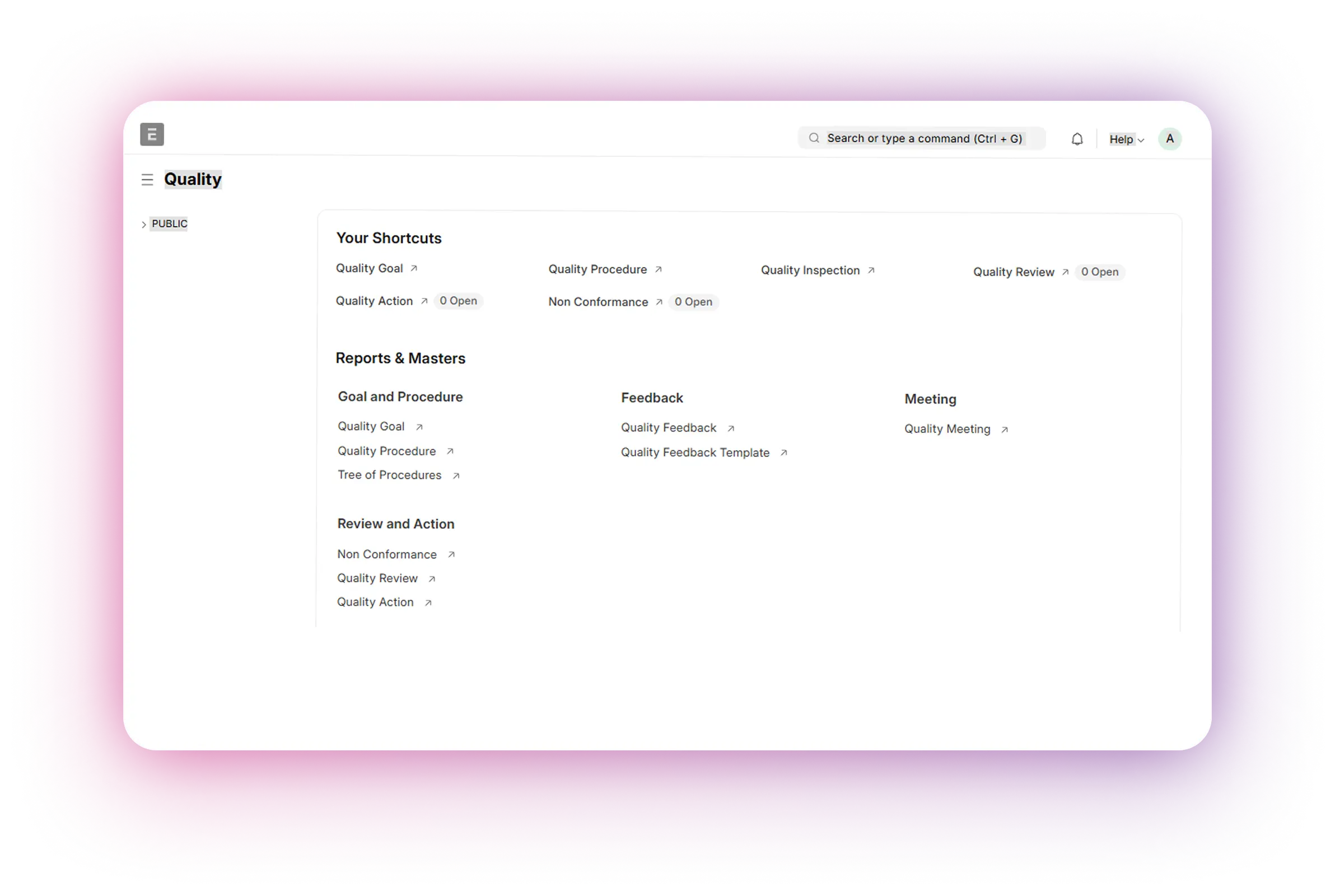

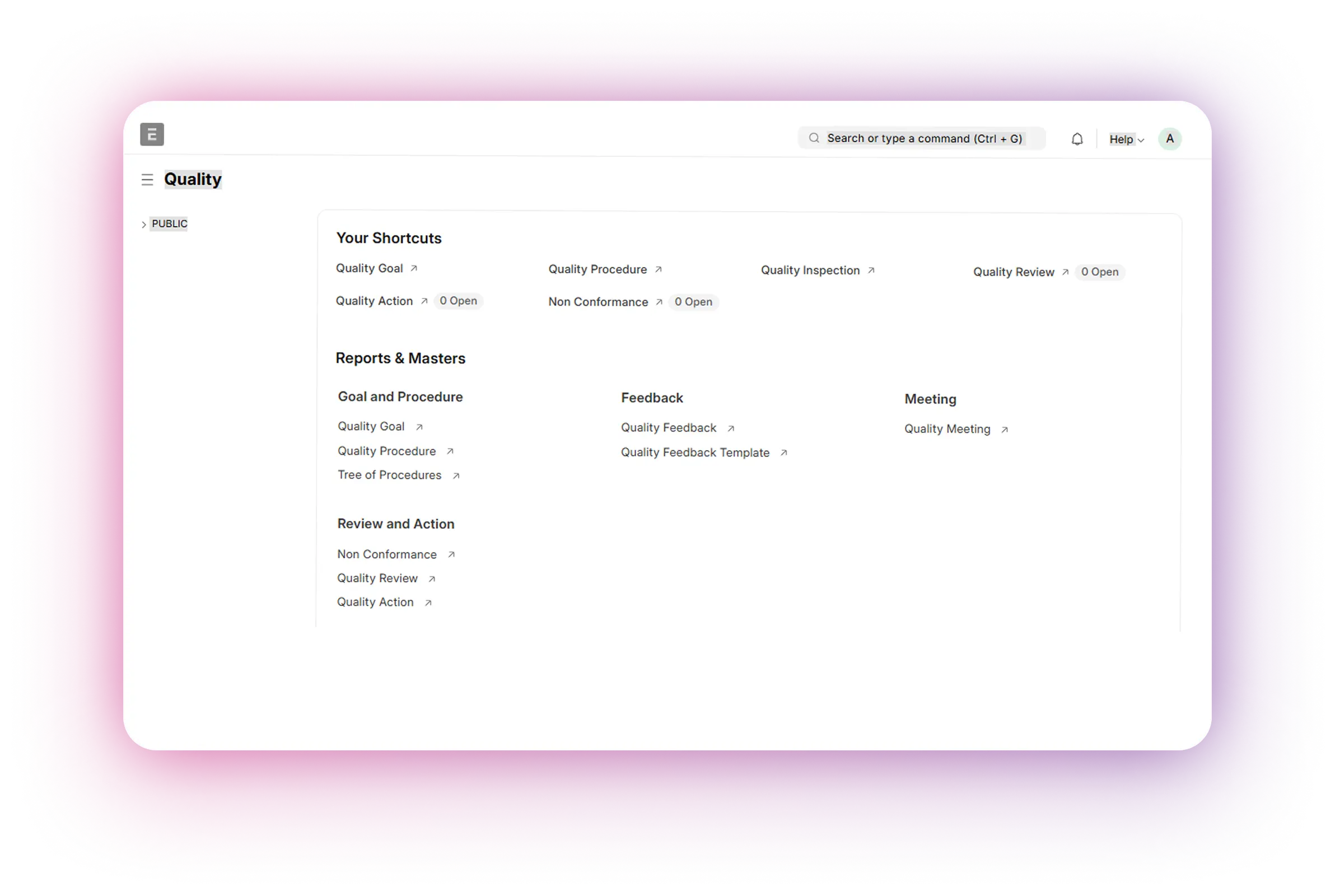

QA Module

QA Module

-

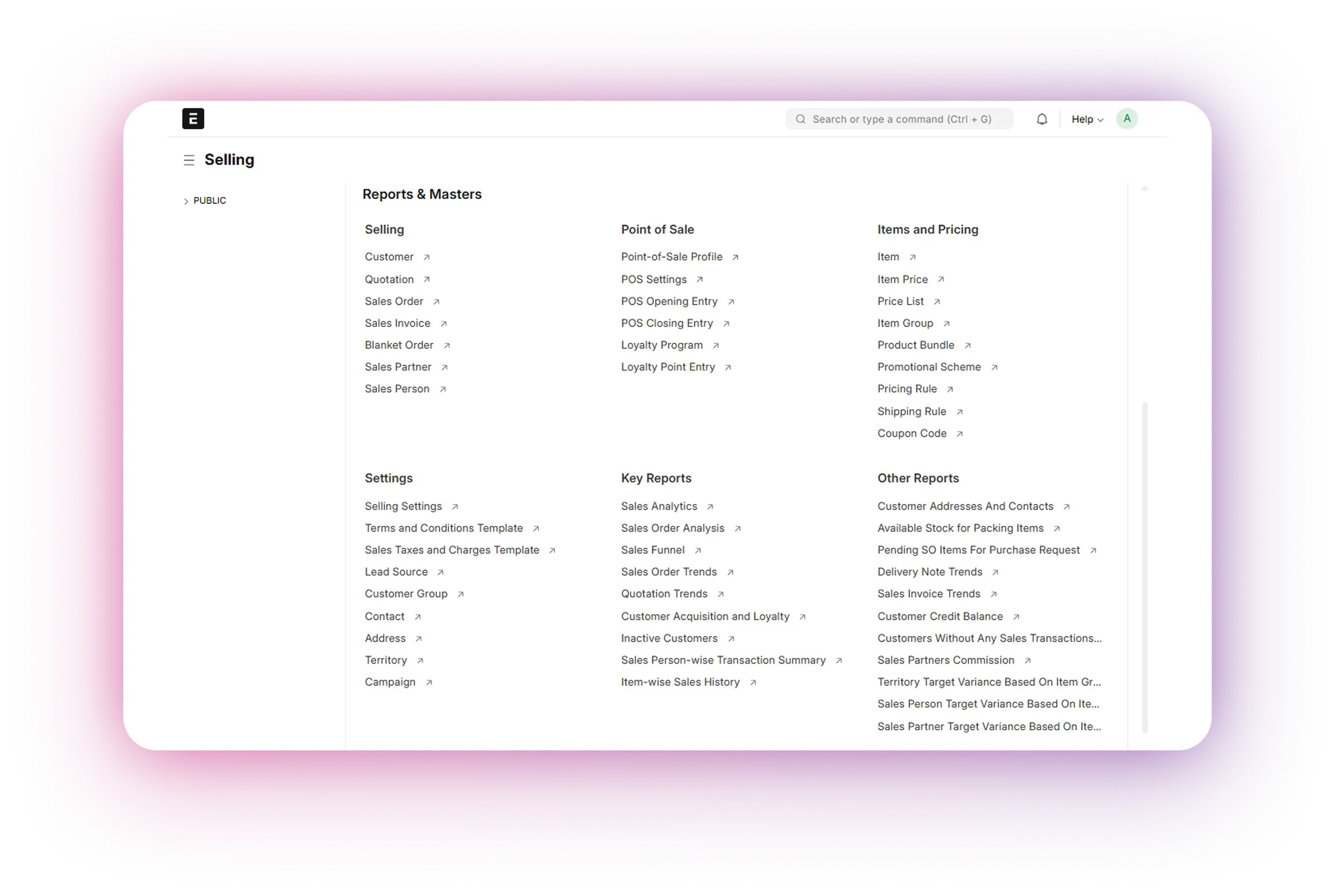

Sales Module

Sales Module

-

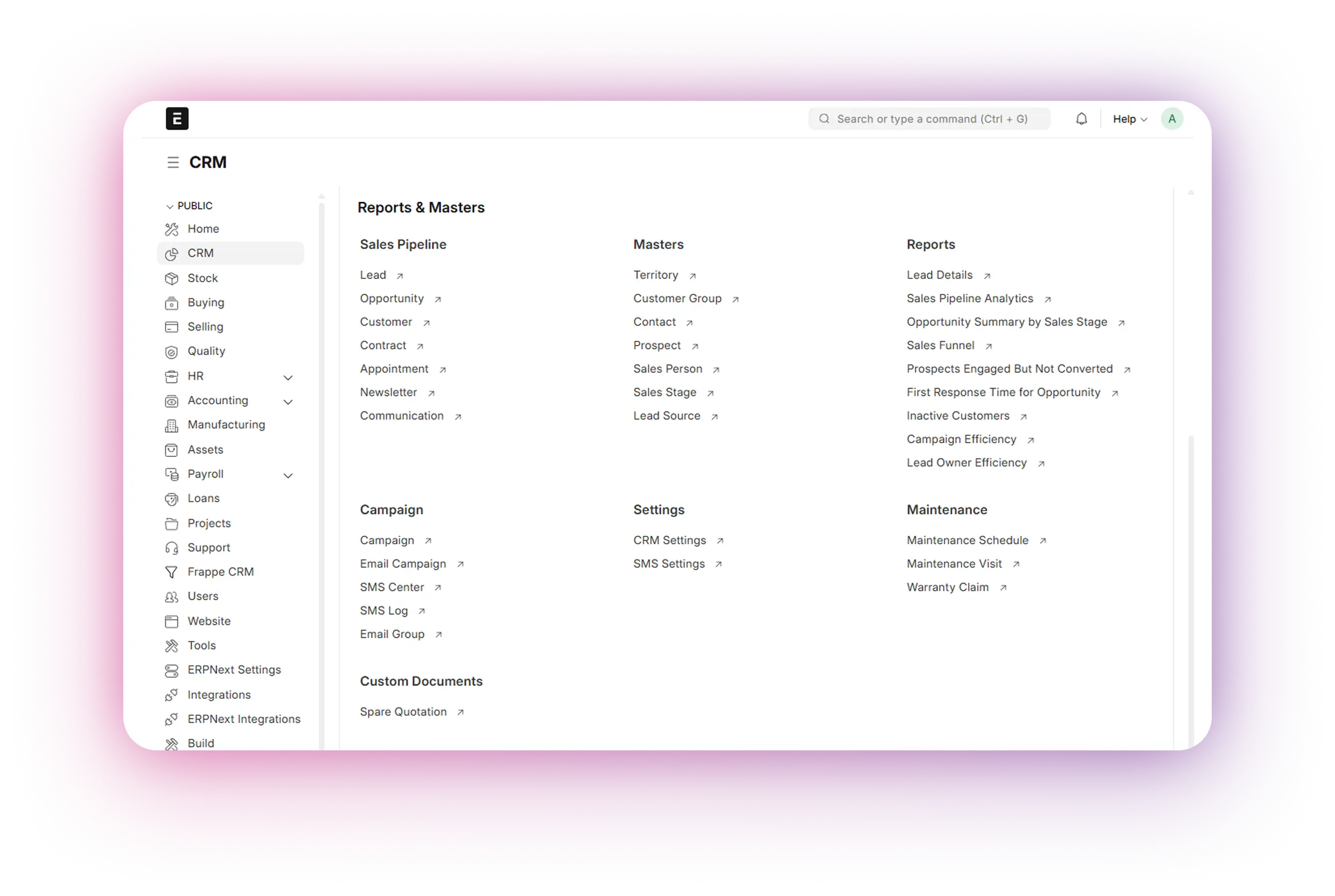

CRM Module

CRM Module

-

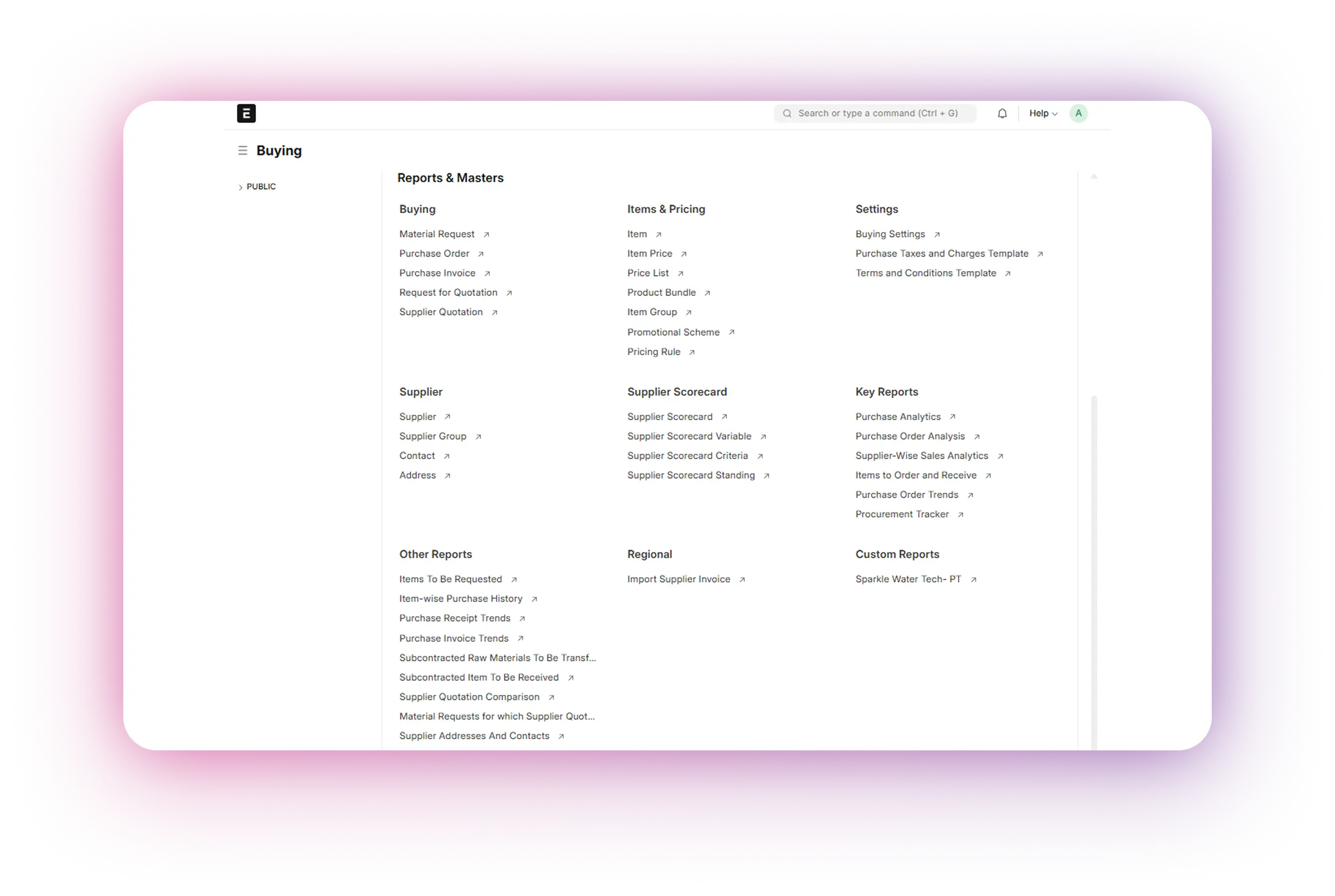

Purchase Module

Purchase Module

Key Reports That Drive Results

Production Reports

Track production efficiency, job progress, and identify bottlenecks in the manufacturing process.

Inventory Reports

Monitor inventory levels, material usage, stock aging, and ensure timely restocking to meet production needs.

Sales and Purchase Analytics

Analyze sales trends, identify top-performing products, and optimize purchase patterns for maximum profitability.

Warehouse Utilization

Ensure optimal use of storage space and streamline inventory allocation across locations.

Financial Reports

Gain insights into your business’s financial health with reports on costs, revenues, and profitability.

Workforce Efficiency Reports

Track employee productivity, monitor machine utilization, and measure labor costs to optimize resources.

Quality Control Reports

Monitor product quality through inspections, track defects, and ensure compliance with quality standards.

Production Analytics

Analyze production efficiency, material consumption, and identify areas for improvement in the manufacturing process.

- Why Software@Work?

Why Choose Software@Work?

30+ years of expertise in Tally & business software solutions

Expertise in manufacturing with a proven track record of success

Dedicated support to help you streamline production and maximize efficiency

- Industry Specific

Solutions Tailored for Your Industry

Auto Parts

Food & Beverages

Chemicals

Furniture

Electricals

Garments

Electronics

Healthcare

Engineering

HVAC

Jewellery

Textile

- Our Client

Our Leading ERPNext Manufacturing Customers

Testimonial

What Our Clients Say About Us

Nobtech Enterprises

Pump Manufacturing

S@W helped us to implement ERPNext as per our company process. Their executives were quite fast to understand our process and then configure the solution. Extended working hours from S@W executive help us to complete implementation fast.

S@W helped us to implement ERPNext as per our company process. Their executives were quite fast to understand our process

Ambika Global Foods & Beverages

Food Manufacturing

We would like to place on record our sincere and deep appreciation for the efforts put by the Software@Work team during the implementation of ERPNext. We have found that the team has completed the project in the timely manner with personal involvement at all levels, which helped us to make us a system driven organization. Modules implemented are CRM, Selling, Buying, Stock, Production, QC, HRMS and Accounting.

We would like to place on record our sincere and deep appreciation for the efforts put by the Software@Work team

AVII Polychem

Plastic Manufacturing & Trading

We have switched to Software@Work services for ERPNext Afrom our existing vendor due to a lack of functional and product knowledge. We feel glad to share that team s@W has highly skilled Functional Consultants with vast industry experience. The flexibility, agility, and scalability are appreciated and it is amazing how open and trusted they are.

We have switched to Software@Work services for ERPNext Afrom our existing vendor due to a lack of functional and product